Our company produces and supply idlers for belt conveyors. LLC “Conveyor Technologies” produces 5 types of idlers: carrying idler, impact idler, suspended, flat carrying idler and self aligning carrying idler. Each type has its own advantages and characteristics. As part of conveyors, our idlers are used in the mining industry, in the food industry, in processing plants and in other areas. Idler – a metal structure designed to install rollers on it and support the conveyor belt, giving it the required shape. The design of the idlers excludes the possibility of the roller falling out of the bracket and damaging the belt with idler when the belt comes off laterally. The main task of idler is to support the conveyor belt, as well as to perform the centering function. By purchasing idlers from us, you are guaranteed to receive a high quality product, competent advice from professionals from our team and delivery on time.

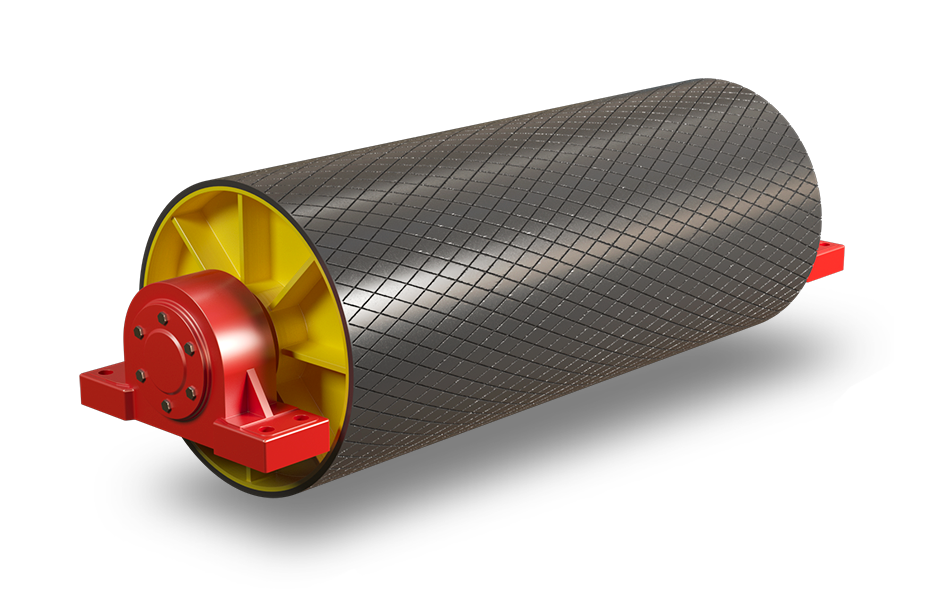

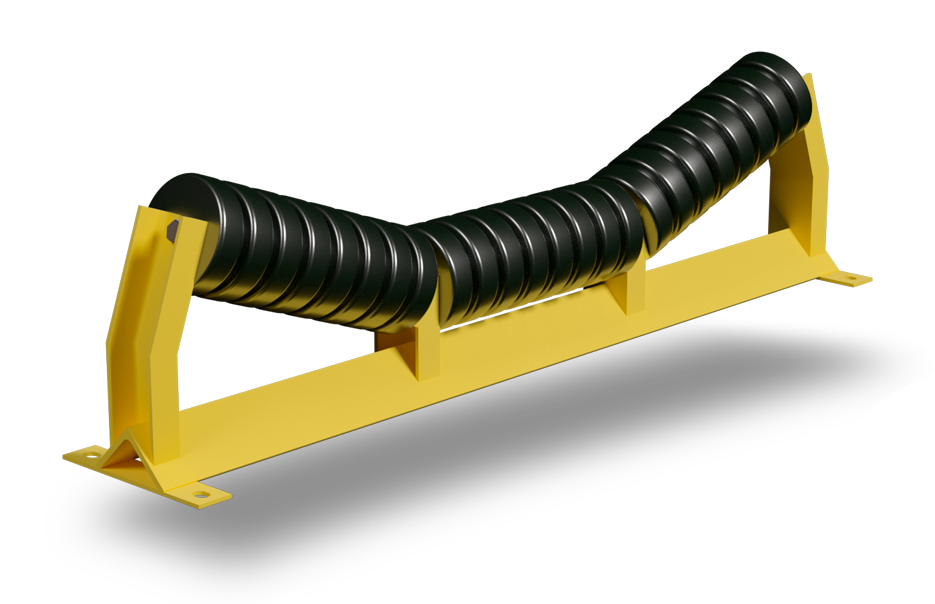

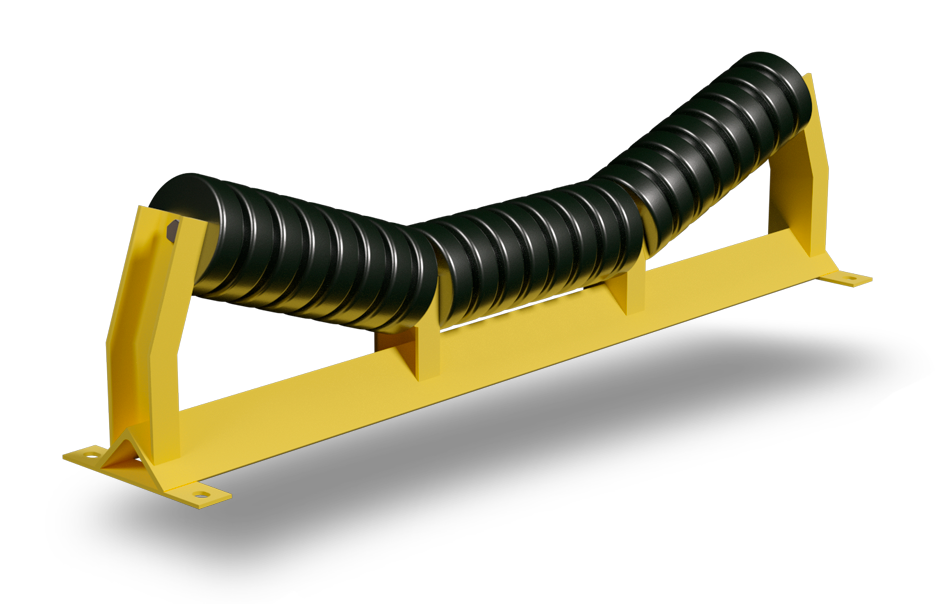

Carrying idler

Carrying idlers are the most common type of idlers and are used to transport bulk cargo. Produced with inclination angles 20 °, 35 °, 45 °. Also carrying idlers can be made according to the requirements and drawings of the customer. To increase the service life of the conveyor, we recommend purchasing idlers with a maximum inclination angle. The width of the conveyor belt can vary from 400 to 2000 mm, and the diameter of the conveyor rollers is 89-159 mm. The highest quality products are on sale, which are certified and have a 12 month warranty. The carrying idler support is a metal structure on which three rotating rollers are installed, the central roller is located horizontally, and the side rollers are at a certain angle.

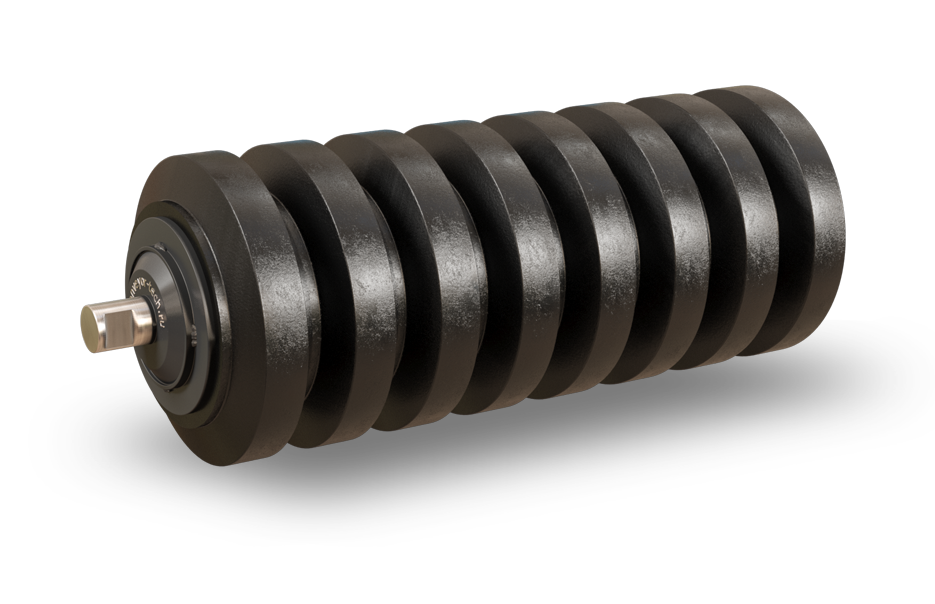

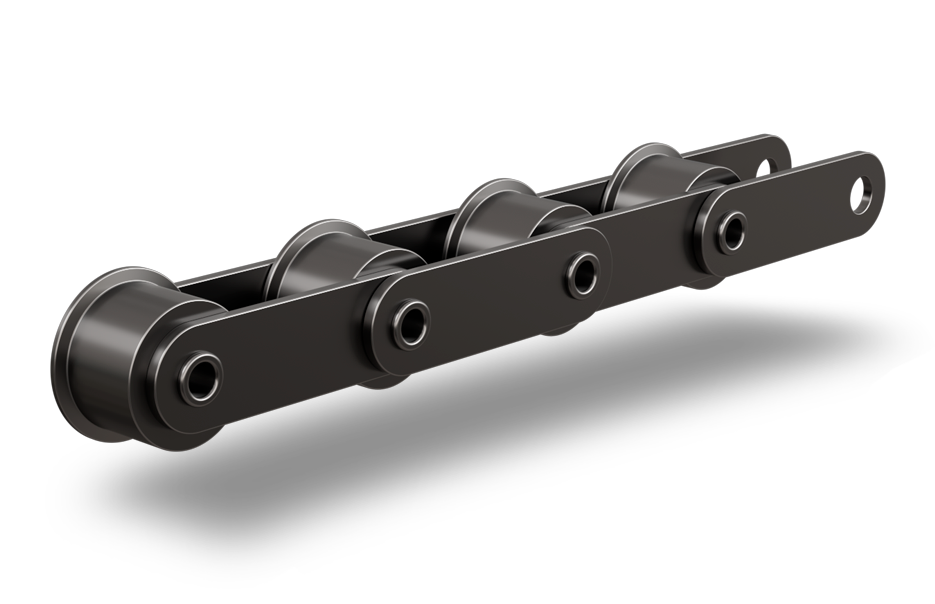

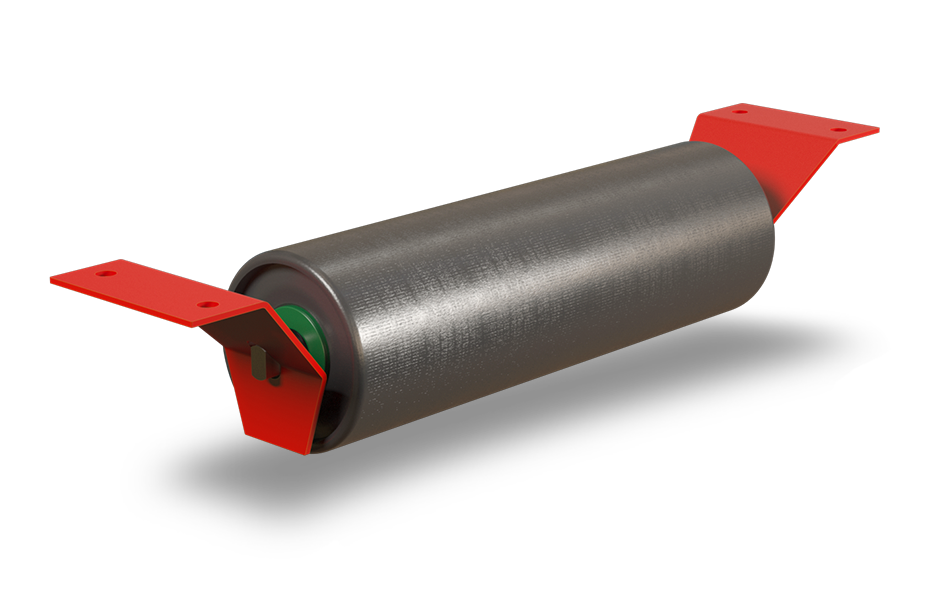

Impact idler

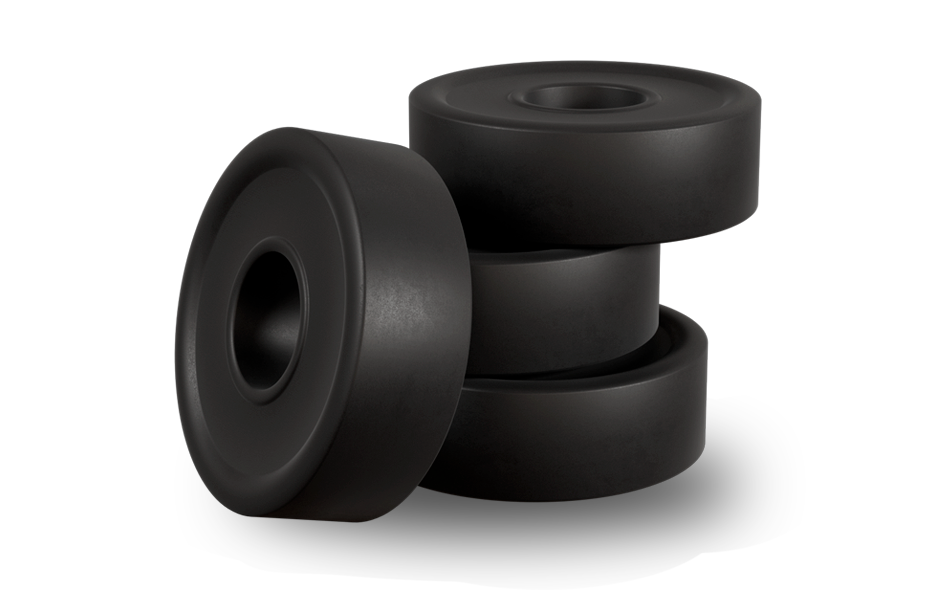

This type of impact idler is used for transporting bulky goods. Heavy weight on the conveyor can damage the conveyor belt. The impact idler is equipped with rubber rings. The locking device and ring sizes are suitably designed for easy replacement, which protects the conveyor belt by absorbing hits at the loading point. Includes three rollers with rollers in one plane, with built-in bearings on through non-rotating axles. The advantages of impact idler are self-cleaning the lower part of the conveyor belt, ensuring a smoother conveyor run and keeping the bearings from premature failure.

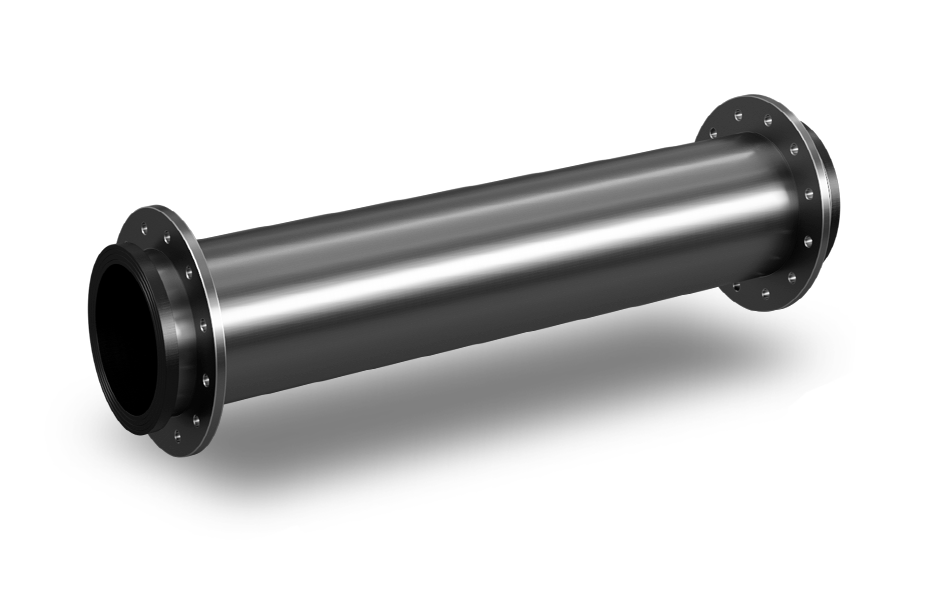

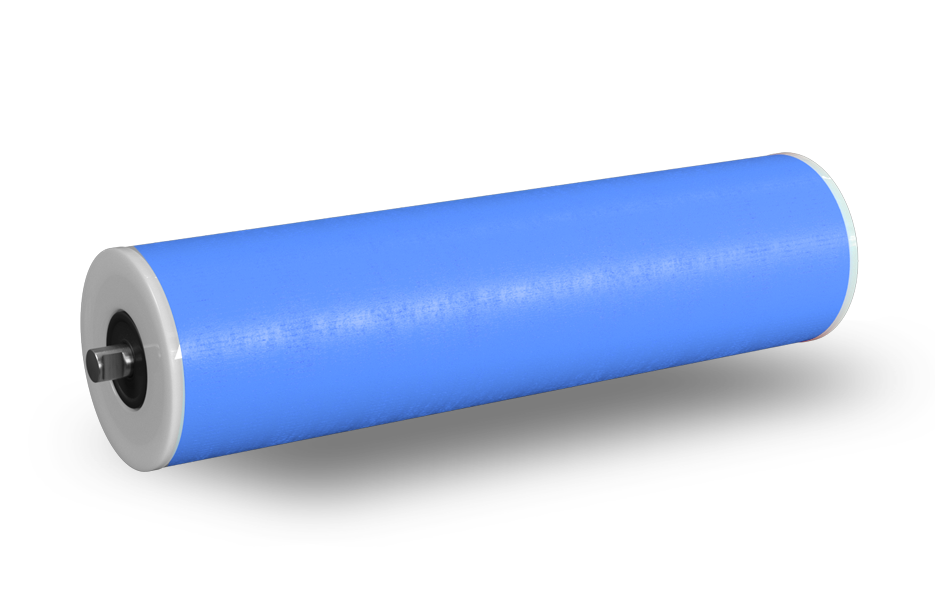

Flat carrying idler

There are two types of flat carrying idler: lower and upper. The top flat carrying idler

is used in the upper part of conveyors in those areas where a flat belt surface is required. The main purpose of the flat carrying idler is to support the flat load-carrying strand of the belt and prevent it from sagging. The lower flat carrying idler

is used to support the lower branch of the belt, installing it on the brackets of the posts of the middle part of the supporting metal structures. In this case, the installation and maintenance of the roller supports is facilitated. Return idlers are installed every 2.4–3 m of the conveyor (the distance between the idlers may be different on sections of the route where there are bulges). The pitch of the flat carrying idler is similar to carrying idler. Rollers can be used smooth, rubber lined and disc. Lubrication of rollers is embedded.

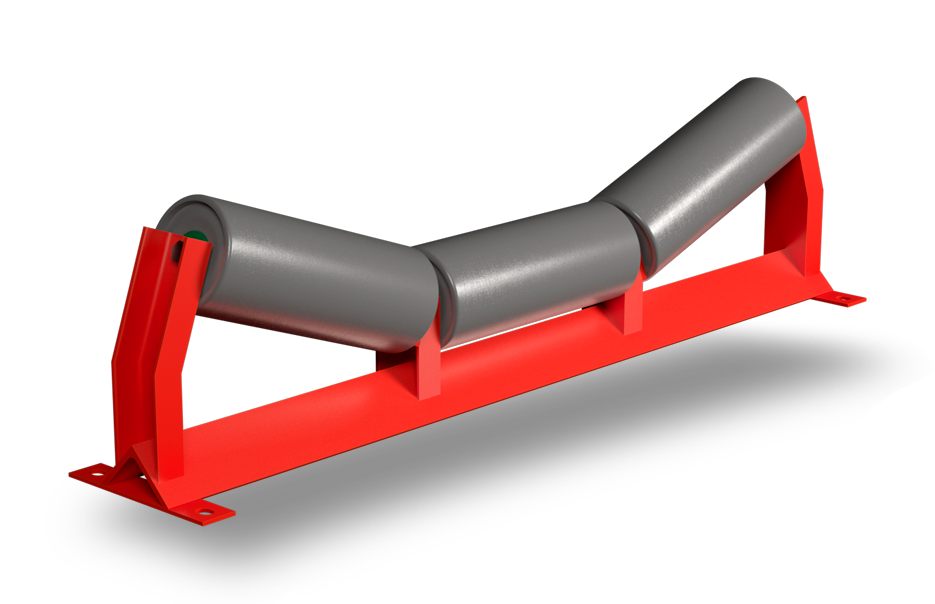

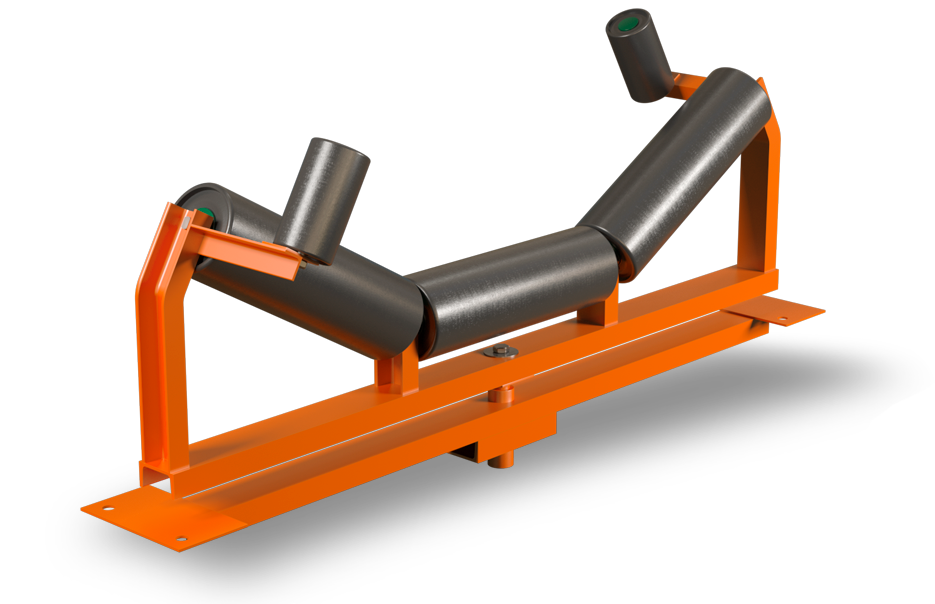

Self aligning carrying idler

Self aligning carrying idler are installed every three to five sections along the length of the conveyor on the cargo and bottom branches of the belt and are used to direct its movement along the conveyor axis when shear forces occur. Centering of the lower and upper branches is of equal importance, since during its descent, friction of the edges of the tape against the posts of sections of metal structures can occur, which will lead to rapid wear of the tape. The same self aligning carrying idlers are used to center each branch. The distance between the idlers of the upper branch is selected depending on the characteristics of the transported cargo, while the distance between the idlers of the lower branch is taken 2-2.5 times more than on the upper branch, but not more than 3.5. These idlers are used to eliminate the misalignment of the conveyor belt from the conveyor.