The conveyor belt recieves the main load during the conveyor operation. A huge amount of cargo of different fractions is constantly transported along it. Unfavorable environmental conditions negatively affect the equipment. In conditions with high levels of moisture, dust and dirt, the rollers wear out very quickly and subsequently fail.

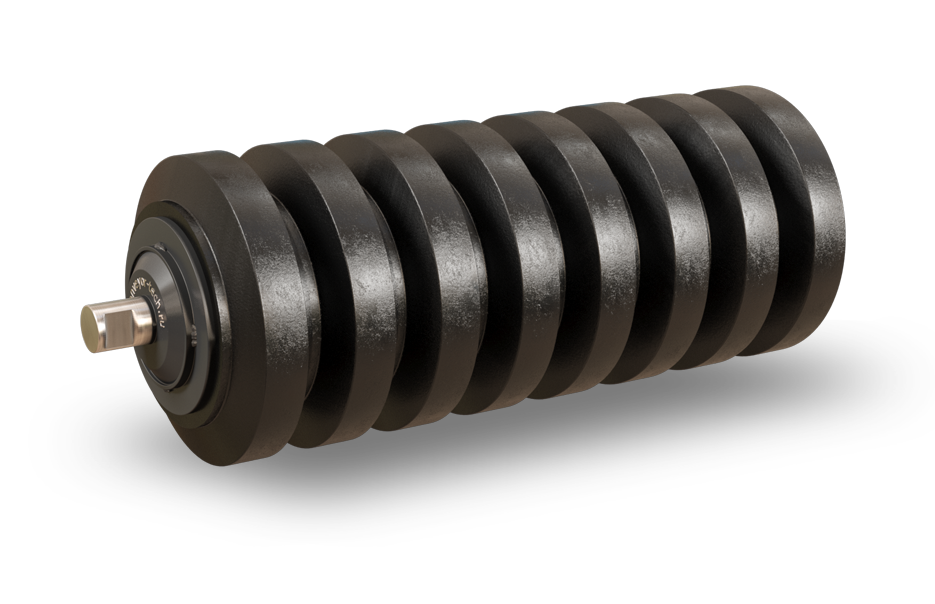

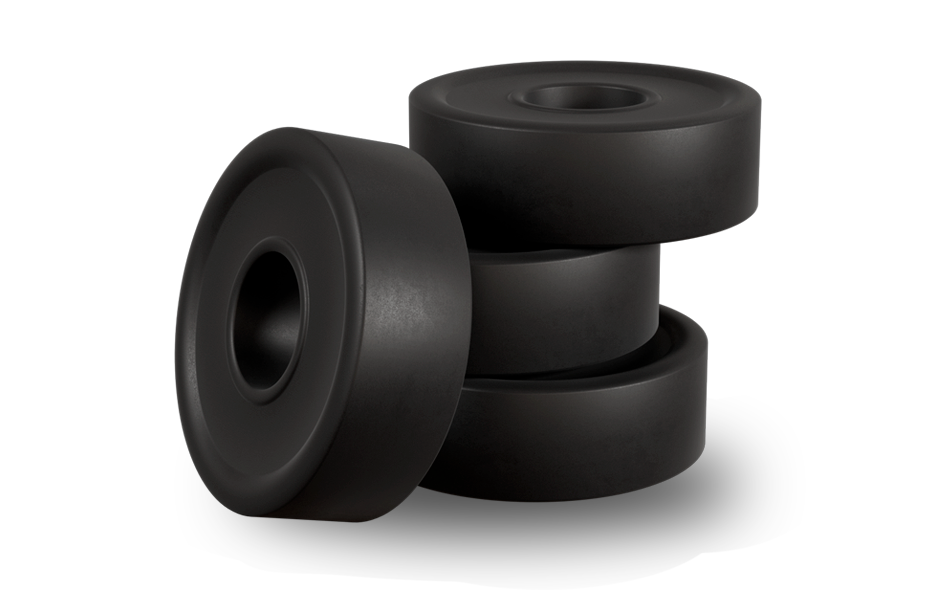

In order to prevent these consequences, LLC “Conveyor Technologies” is engaged in the production of rubber shock-absorbing rings for rollers.

Rubber rings extend the service life of not only the conveyor rollers, but the entire conveyor belt.

Rubber rings are manufactured in accordance with GOST 9833-73.

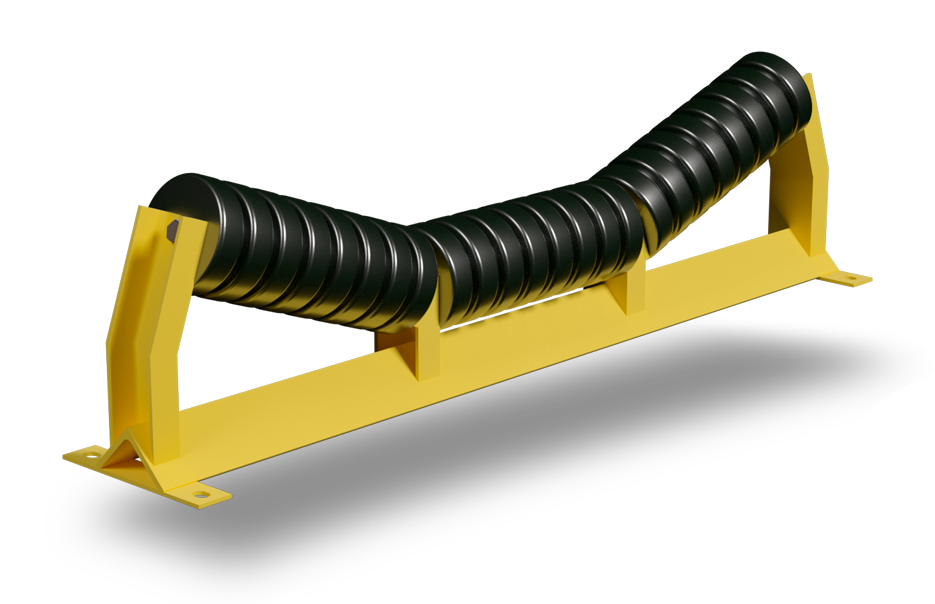

Rubber rings are installed on the roller shell, which significantly soften impacts at the loading points on the conveyor belt. They also reduce vibration, significantly extending the life of the bearing assembly and conveyor belt. Made of wear-resistant and shock-absorbing rubber. Rubber rings for lining cargo and supporting rollers of conveyors are produced for rollers with a diameter from 54 mm to 159 mm. Before entering production, materials undergo technological examination for compliance with GOST, which allows us to produce high quality products, which are excellent for lining both the cargo and supporting legs of the conveyor belt.

Rubber rings have several advantages:

– the roller bearing is protected from premature failure;

– assistance in saving the conveyor belt when large loads fall;

– prevention of decentering of the conveyor belt

Rubber rings are used in places where equipment is regularly subjected to increased wear and tear and is under severe stress. In heavy industry, in mines, on railways and in many other industries. LLC “Conveyor Technologies” recommends installing rings not only at the loading points of the conveyor belt, but also along the entire length, which will significantly affect the service life of the conveyor itself.