The company LLC “Conveyor Technologies” specializes in the production of conveyor rollers. LLC “Conveyor Technologies” produces conveyor rollers from 200 to 2700 mm in length and 76 to 219 mm in diameter with bearings 6204, 6305, 6306, 6307, 6308, 6310 and 6312 of closed series 180 … or 2RS. All rollers are manufactured in accordance with GOST R 57841-2017 and TU 28.22.10-001-95408555000-2019. Warranty for all types of rollers is 12 months from the date of commissioning.

For production, our company uses high-precision electric-welded steel pipes GOST 10705-80, since the ovality of the steel pipe directly affects the radial runout of the rollers and the resistance to rotating friction. The electro-welded pipe we use for production is a special pipe for conveyor rollers only, with a slight curvature, uniform wall thickness and removal of internal and external burrs from the pipe.

Pipe cutting is carried out on an automatic cutting machine with CNC, which ensures high accuracy of the conveyor rollers shell length.

The shaft is one of the main parts of the conveyor roller, that is why all conveyor rollers manufactured by OOO Conveyer Technologies are made of a high-precision calibrated wheel GOST 1050-88, which has high strength and hardness which guarantees high quality and service life of the conveyor roller. Chamfering and locking grooves are made by CNC lathes, precise positioning of the locking grooves effectively reduces the axial movement of the roller.

The bearing housing is made of steel sheet with a method of stamping. The formation of the bearing housing is carried out in 8 stages, which ensures high accuracy and compliance with all requirements for fitting, alignment and parallelism of the bearing housing surfaces. The bearing housing and shell of the conveyor roller are welded together on special CNC welding equipment, which guarantees the alignment of the conveyor roller.

Ball bearings 6204, 6305, 6306, 6307, 6308, 6310 and 6312 are the main elements of conveyor rollers. Quality ball bearings can significantly extend the life of the conveyor roller. Our company can equip conveyor rollers with ball bearings of well-known manufacturers at the request of the Customer.

The conveyor roller adopts a non-contact labyrinth seal structure. The free space between the labyrinth seals is additionally filled with Litol-24 grease, which additionally prevents dirt and dust from entering the conveyor roller.

Our company has modern equipment for blasting the surface of conveyor rollers, followed by powder painting in an automated spray booth.

All parts of the conveyor rollers undergo strict quality control of the manufactured products to ensure smooth operation of the conveyor.

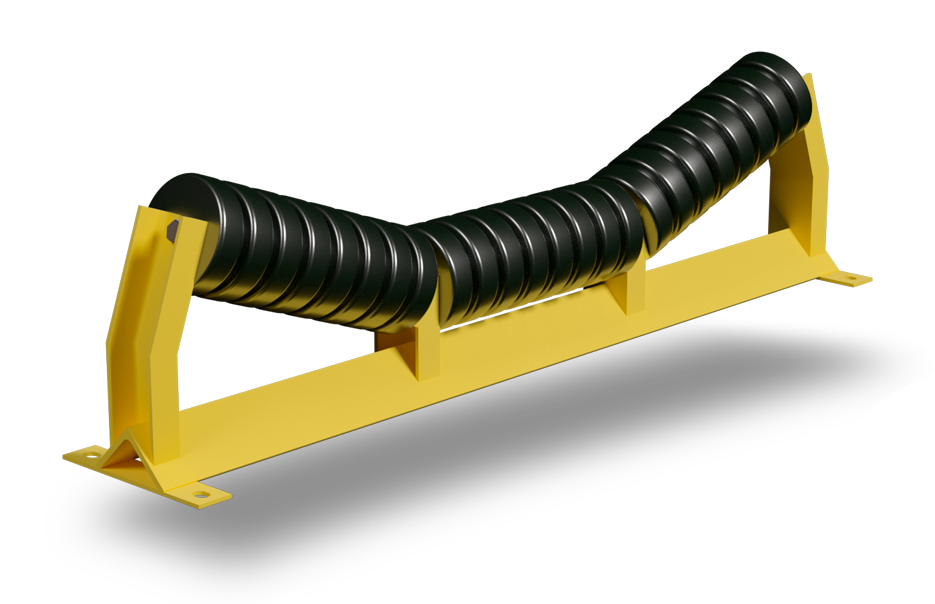

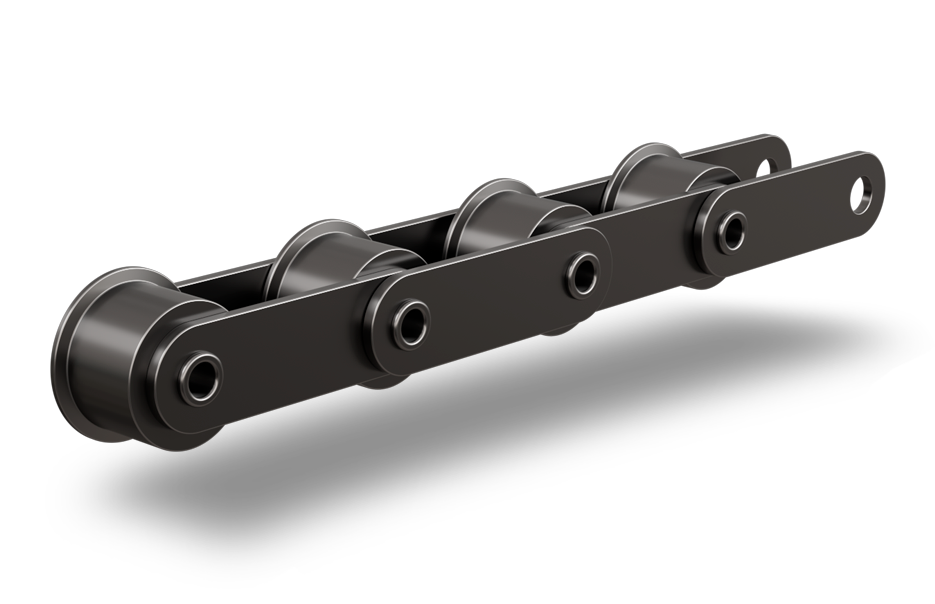

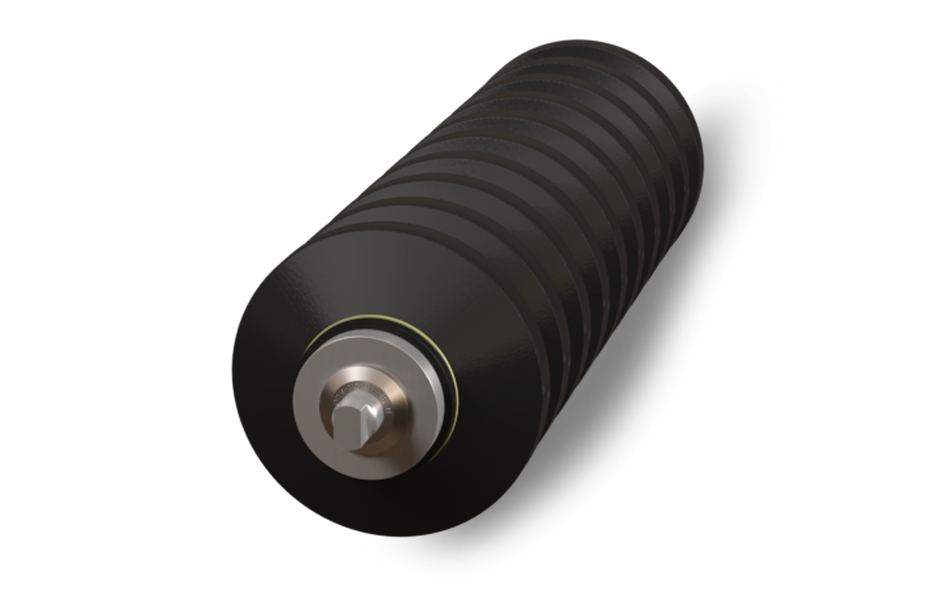

Impact roller

The main feature of Impact conveyor rollers is to soften hits in places of increased conveyor load when using rubber rings of different profiles. The diameter of the rings varies and depends on the customer’s requirements. Impact conveyor rollers increase the life of the conveyor, reduce the noise level in the facility and dampen vibrations that occur during the operation of the conveyor.

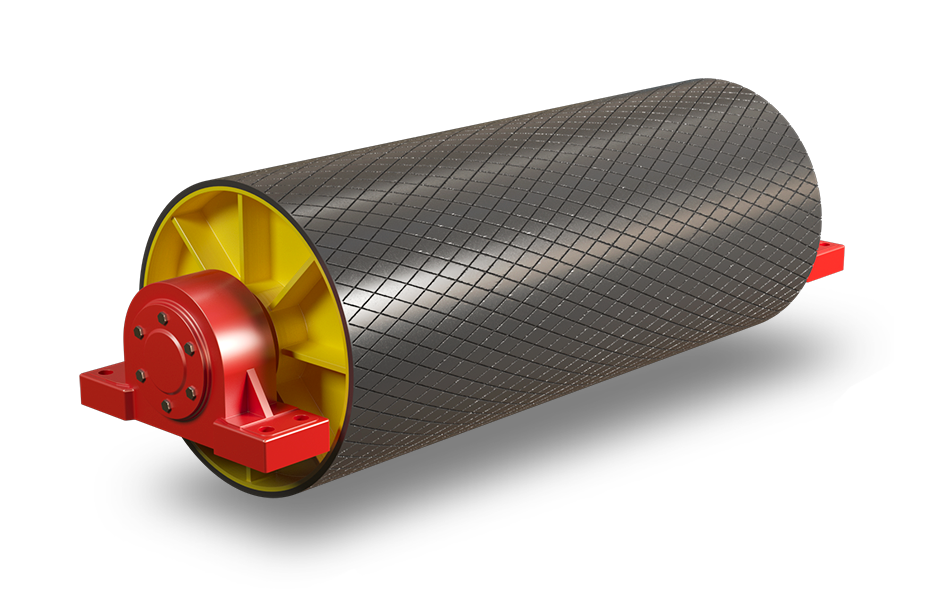

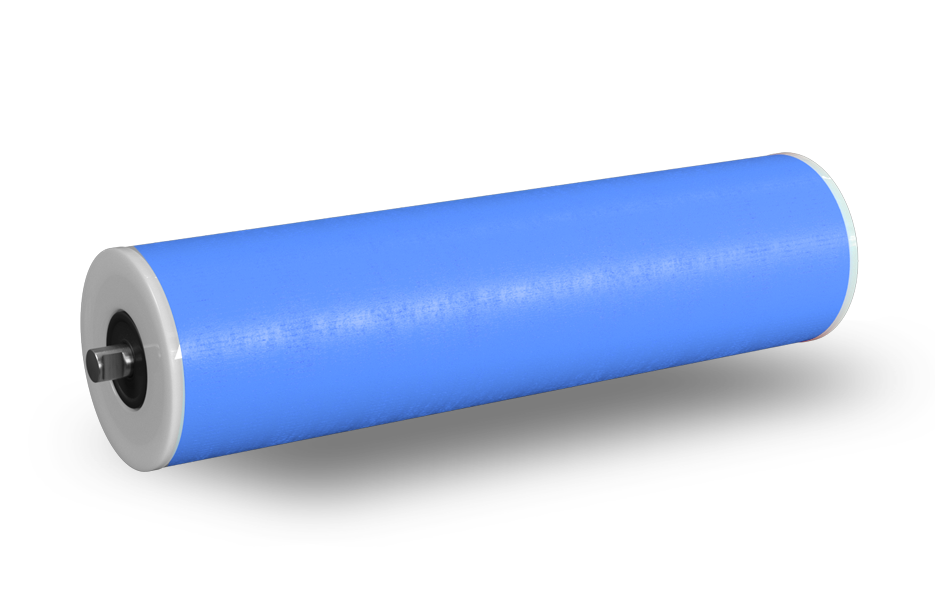

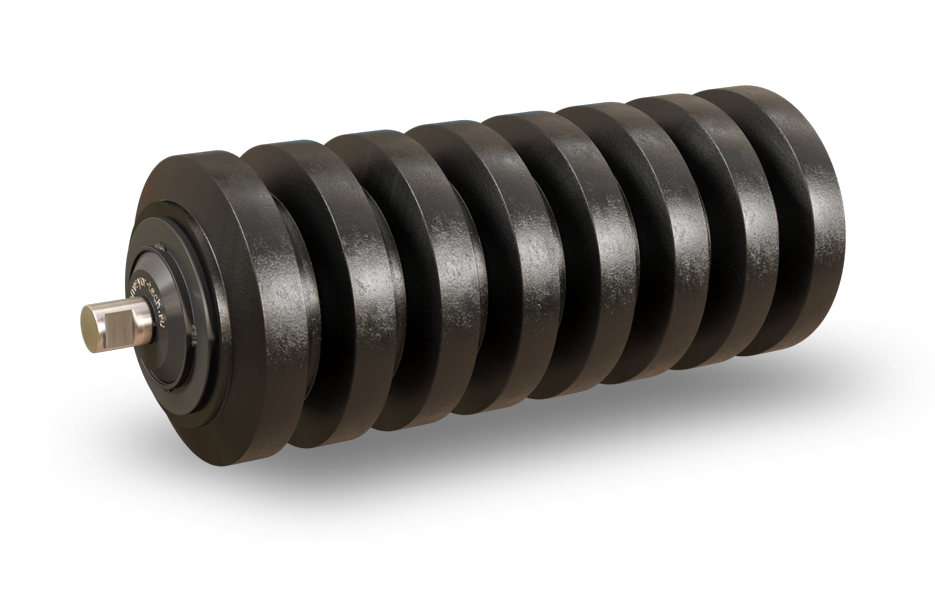

Smooth rollers

The use of this type of conveyor rollers reduces the noise level during the operation of the conveyor, they are also designed for work at low temperatures and are excellent for moving loads of various weights. The main task of a smooth roller is to reduce the resistance of the conveyor movement, support and form the protection of the conveyor belt, and it also works as a limiter against displacement of the conveyor belt in different direction.

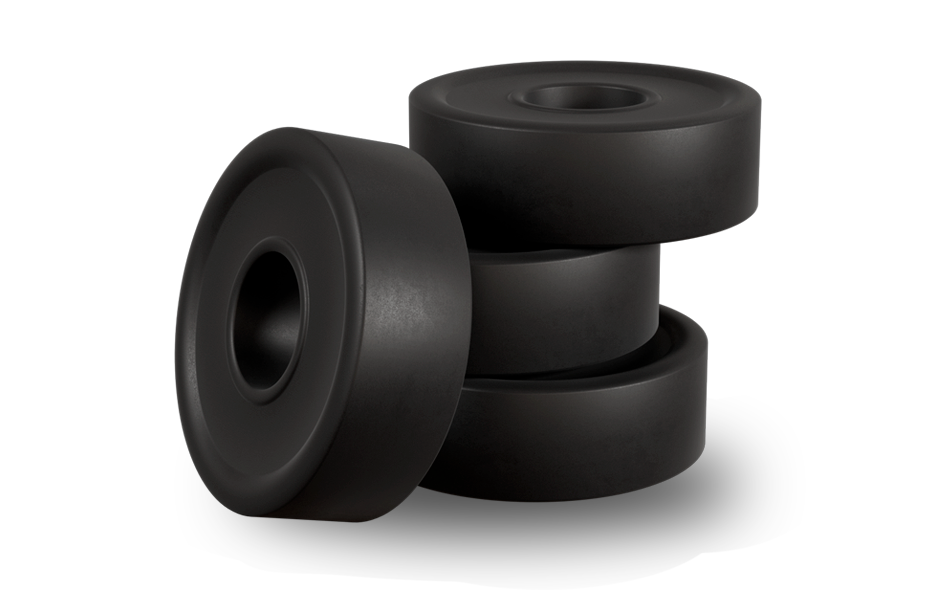

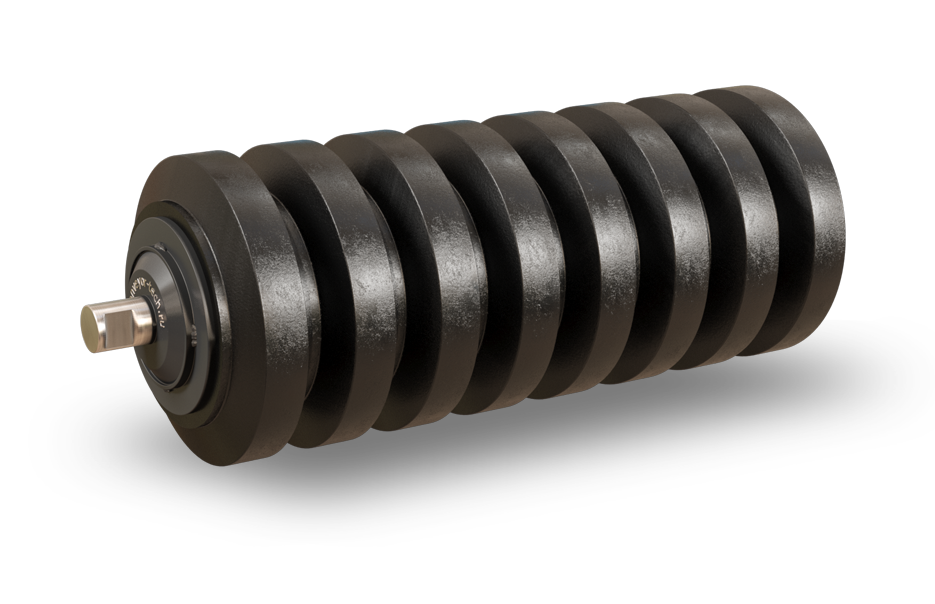

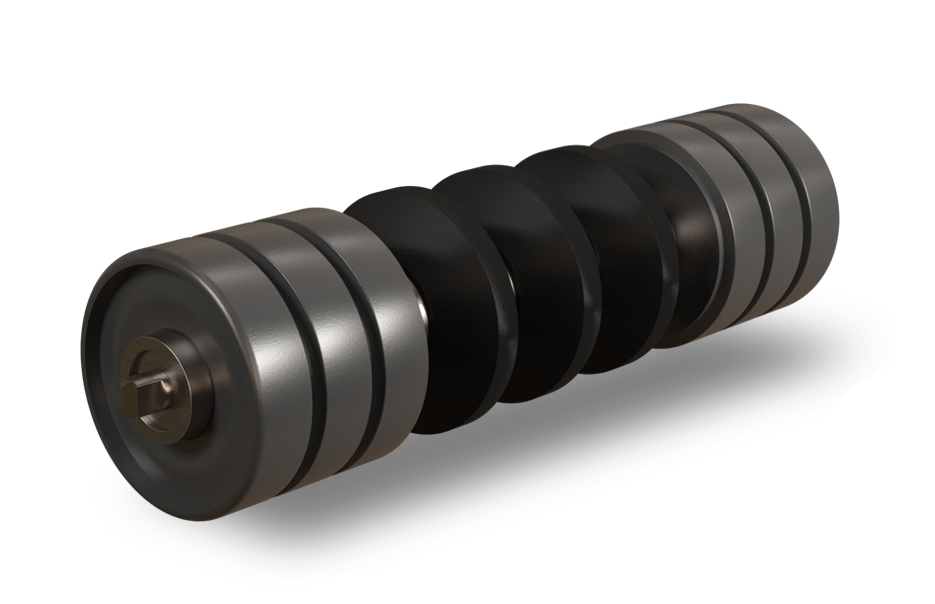

Disc conveyor rollers

Disc conveyor rollers support and form the lower connecting pull of the conveyor belt in reverse motion and remove adjacent material from it. Used where sticky materials stick to the belt and cause corrosion, this roller uses durable rubber discs. Depending on the application, three backing pad materials are available: rubber, polyurethane and ceramic, which prevent carryover and extend roller life. The disc rollers are made of powder-painted steel tube, on which special discs are put on.

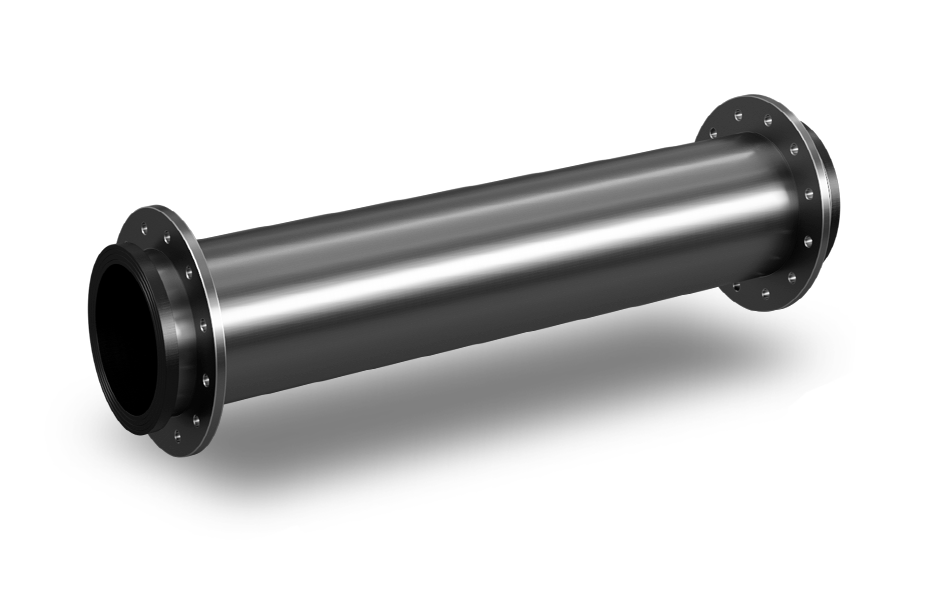

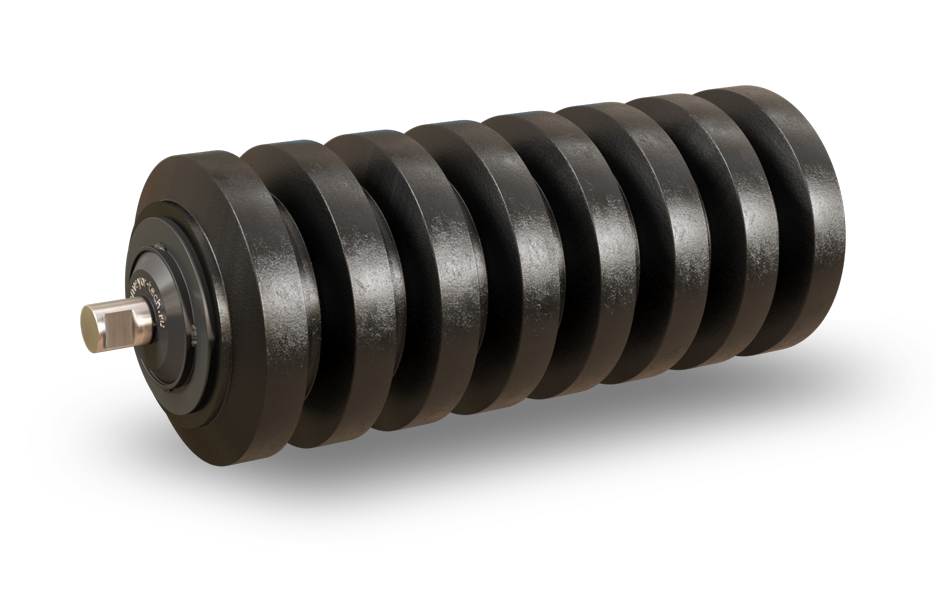

Scrubbing conveyor rollers

Scrubbing conveyor rollers are well suited for the mining, quarrying and processing industries where ore build-up on the return conveyor rollers results in conveyor belt damage and incorrect tracking. The cleaning conveyor rollers are resilient and durable rubber, polyurethane, or steel spirals that help remove sticky residues in conveyor systems. Consists of a standard smooth roller with special profile rings. Scrubbing rollers can be used on any part of the return conveyor belt section on short conveyors while they are beneficial to use over long stretches only until the material no longer attached conveyor belt.