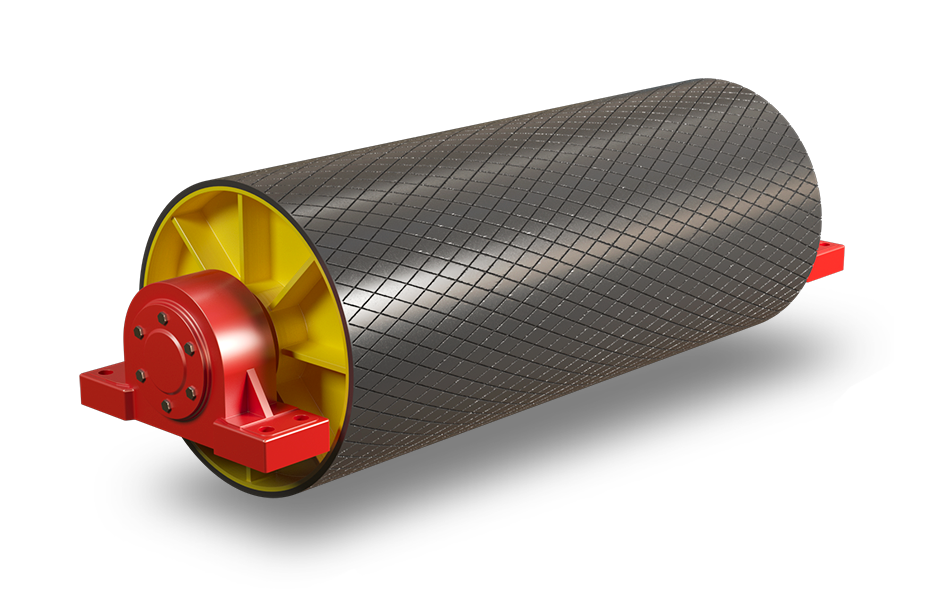

The company LLC “Conveyor Technologies” is engaged in the development and production of spare parts for the apron conveyor. Plate conveyors are in great demand and are designed to transport various materials in horizontal and inclined planes. Most often conveyors are used in the metallurgical industry, they are installed for transporting ore of various sizes. In the mechanical engineering field, transportation of hot castings, forgings, stampings and many other blanks is often carried out. Apron conveyors have a number of positive characteristics and advantages. Design features allow you to create inclined and other types of apron conveyors. High degree of adaptability to the transportation of hot, sharp-edged, lumpy and other goods that can cause damage to the surface of the conveyor belt. This moment determined the widespread use of apron conveyors in industry and many other areas.

A high degree of productivity is also one of the main advantages of the apron conveyor. All products of our company are certified and meet high safety and quality requirements.

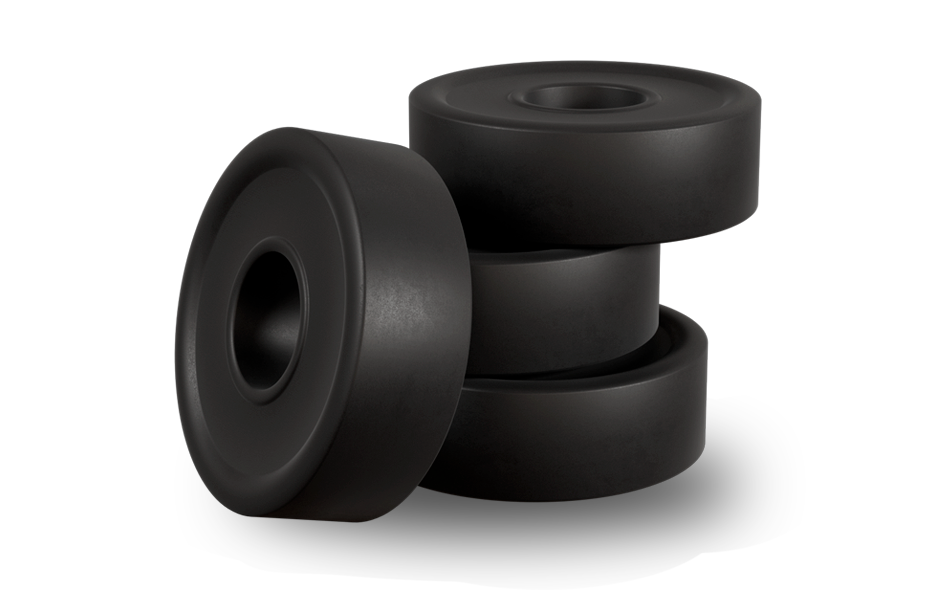

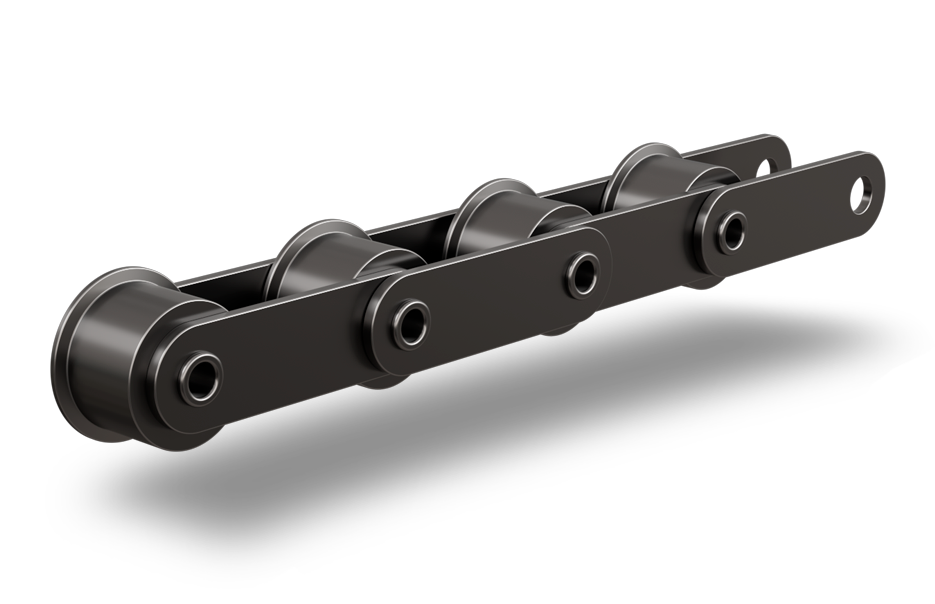

Lamellar traction chains

Lamellar traction chains consist of a series of interconnected internal and external links that can move freely in one plane. These chains are manufactured using a special technology that ensures their long service life under the established working loads. The main advantage of our chains is versatility and ease of use, due to the possibility of equipping the chains with various attachments for transporting various materials.These chains are very effective and find their application in various fields and industries.

Lamellar traction chains have a number of technical characteristics that depend on the wishes of the customer:

1) The material from which the chains are made (depends on the area of further application).

2) The presence of special fasteners on the chains or their absence.

3) One of the most important parameters is the pitch of the traction chain.

4) Load.

5) Width between plates.

6) Thickness and width of the inner plate.

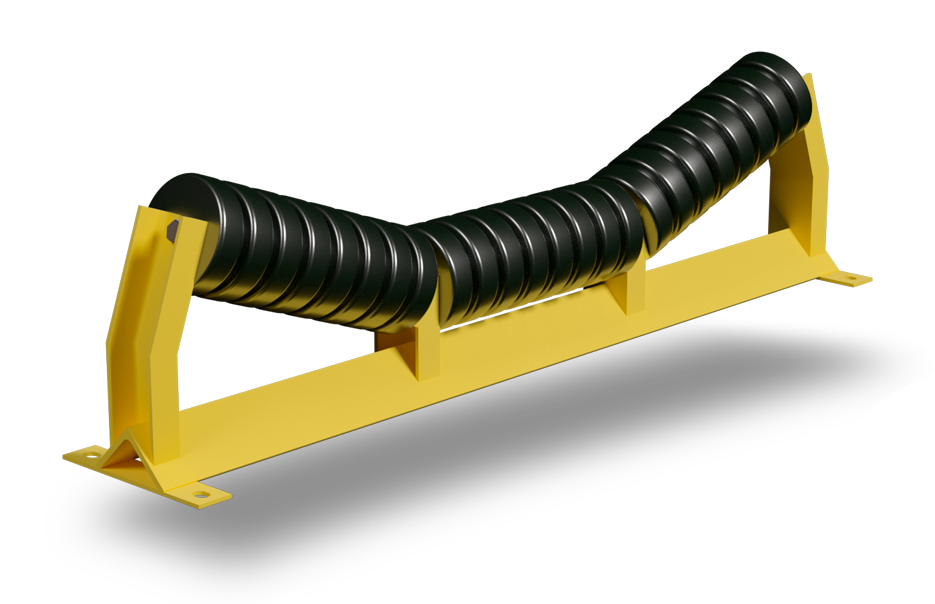

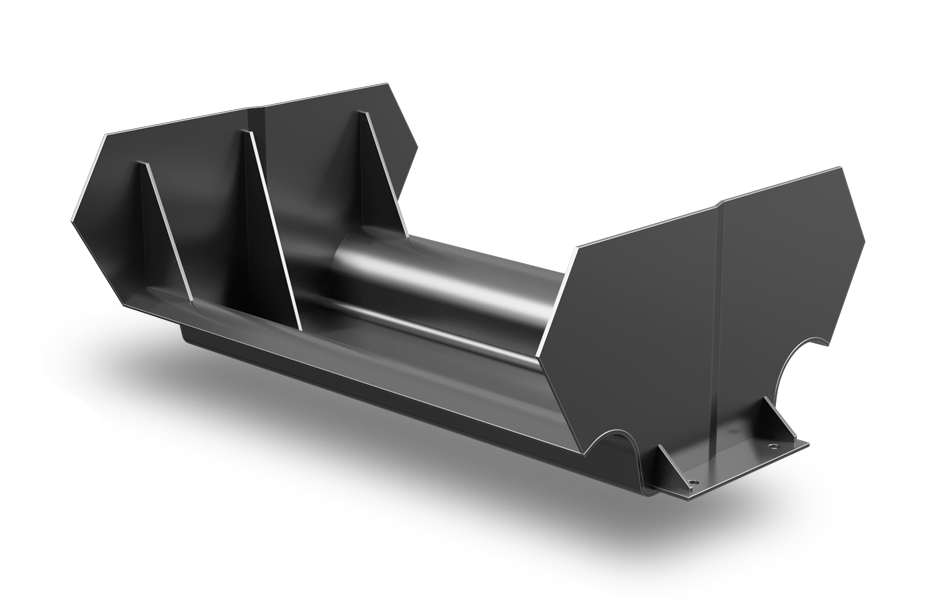

Plate conveyor tray

The tray is the supporting part of the plate conveyor. The trays are connected to the lamellar chain of the conveyor and must be located 2 trays per one running meter. The tray rests on uprights that are attached to chain plates.

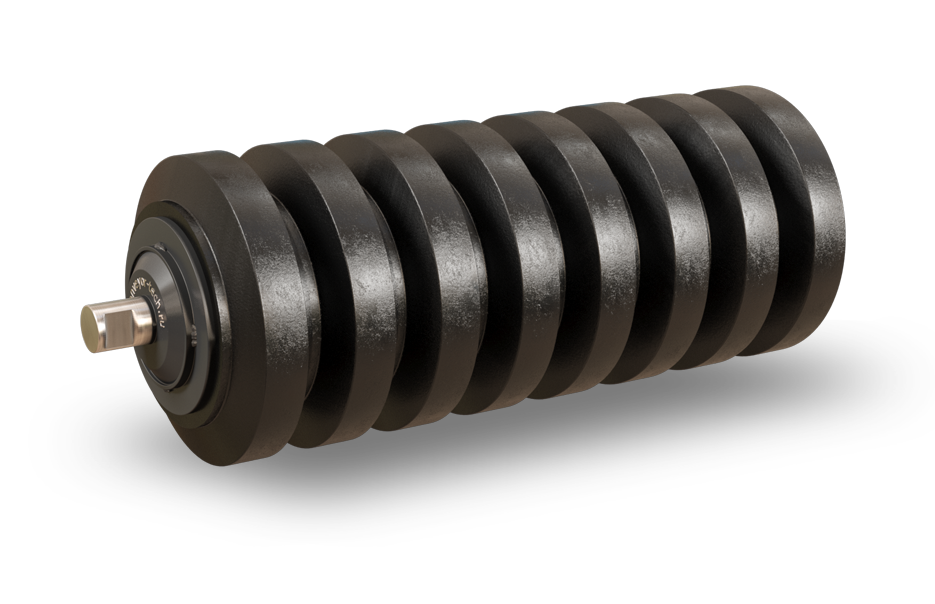

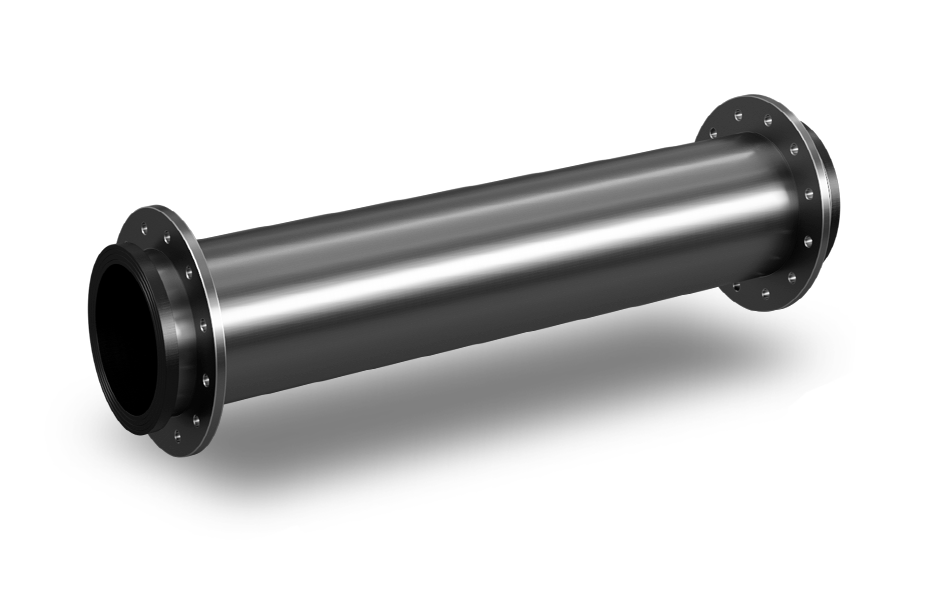

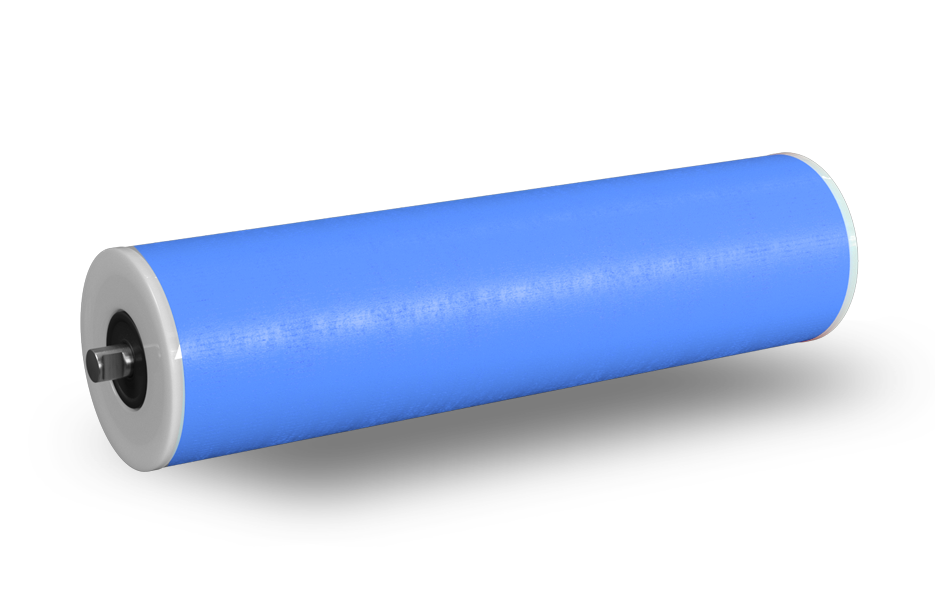

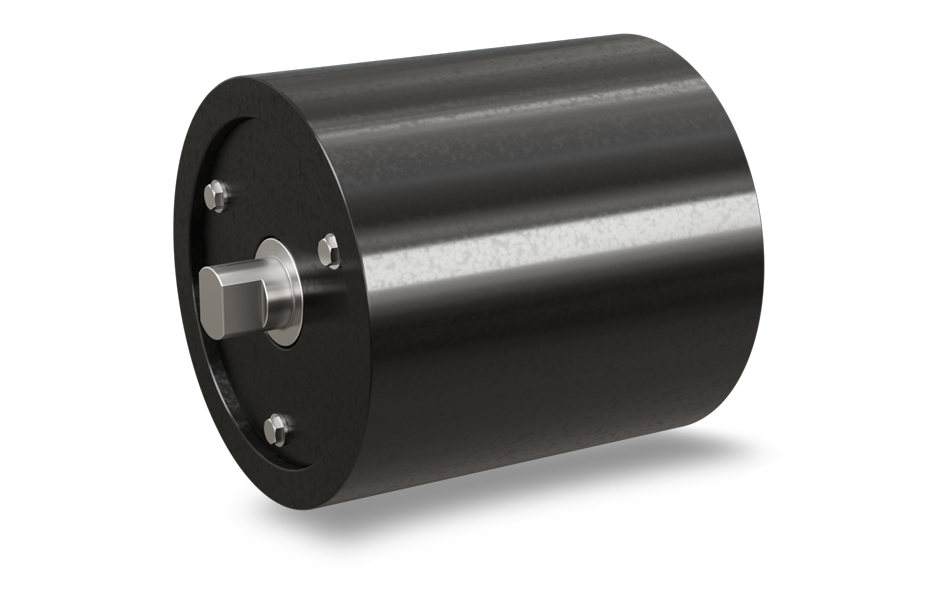

Plate conveyor roller

The rollers are used to support the chains of heavy apron conveyors and are attached on thru axles or cantilever axles to the plates. Roller diameter 180 mm. The rollers can be made to order at the request of the customer. The advantages of this roller include the increased thickness of the shell and its heat treatment, which significantly increases the service life of the rollers. Also, the reliable fastening of the sealing caps by bolting and the absence of stop beads allows for a more straightforward movement of the lamellar chain.