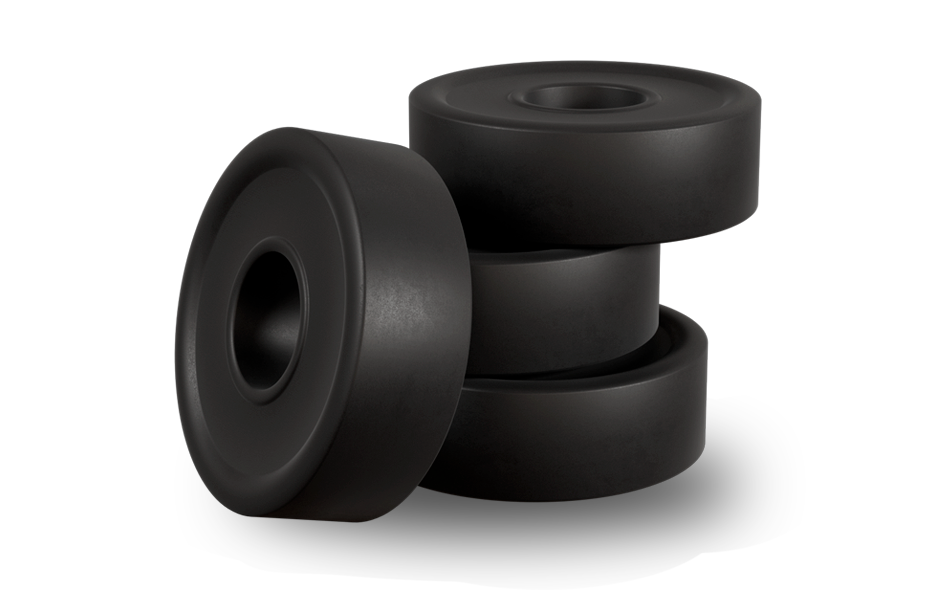

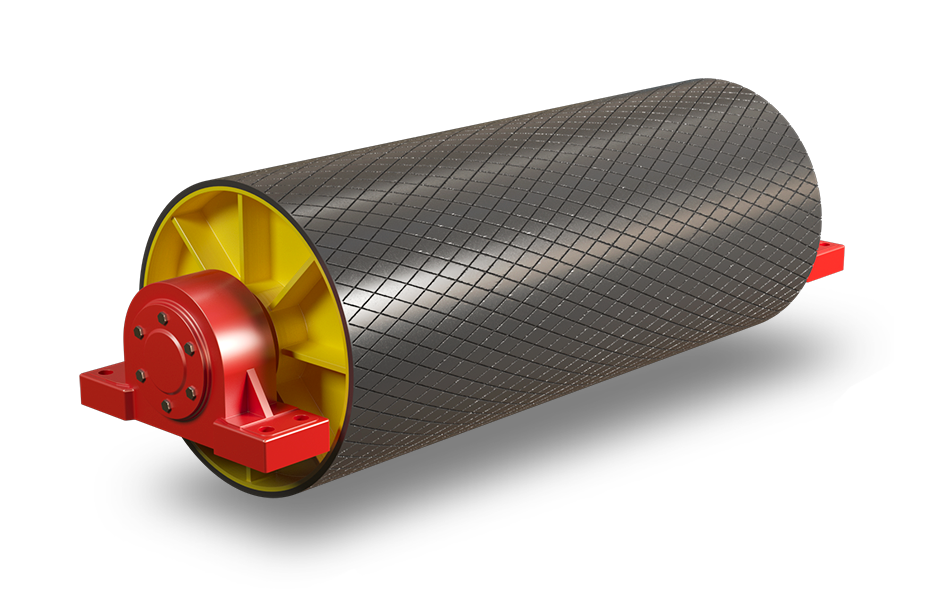

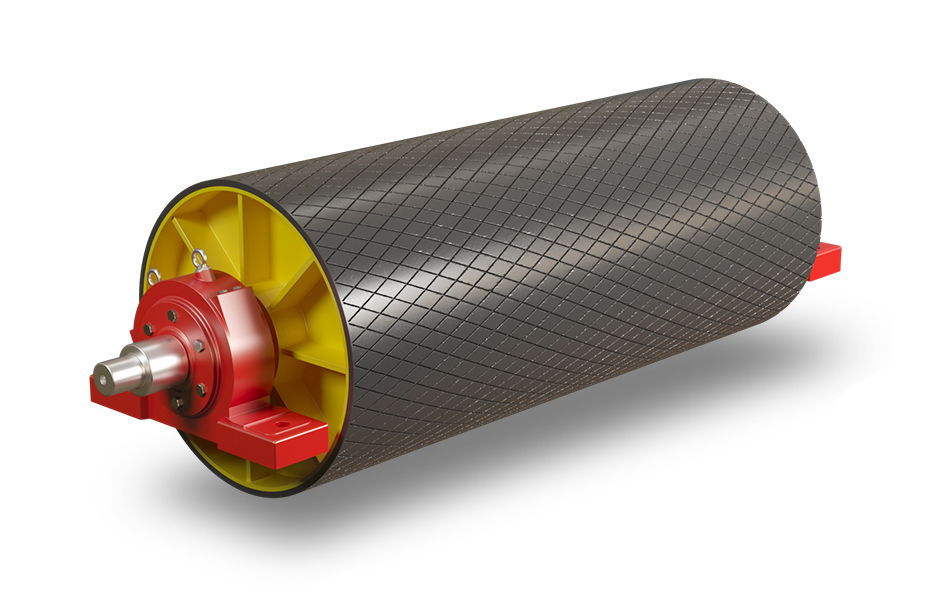

LLC “Conveyor Technologies” manufactures four types of conveyor pulleys: drive pulleys, non-drive (tilting) pulleys, tension and self-cleaning pulleys. Each type of pulley can be lined with rubber, ceramics, rubber – ceramics and other materials at the request of the Customer. The pulley lining can be smooth, diamond-shaped and chevron-shaped (with ribs counterclockwise or clockwise).

The lining of the pulley allows to increase its service life and the durability of the shell by increasing the tractive effort and the coefficient of friction between the conveyor belt and the conveyor pulley.

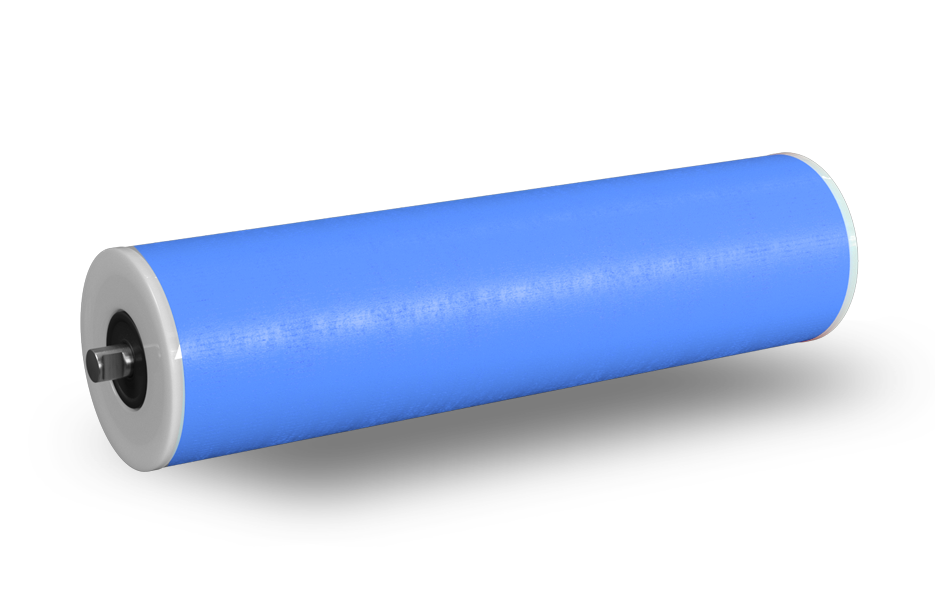

Non-driven (tilting) pulleys, stretch and self-cleaning conveyor pulleys are supplied without linings.

We design and manufacture our conveyor pulleys using innovative design and state-of-the-art technology. Quality control is carried out at every stage of production, which ensures the high quality of the conveyor pulleys. All types of conveyor drums are covered by a 12 month warranty. The drums are cylindrical or barrel-shaped. Bearing unit – with internal or external location. In the production of drums of any modification and purpose, the most important thing is compliance with all technological stages, in time operational control and the use of only high-quality materials and parts. The pulleys are used to complete conveyors that are used in such industries as: mechanical engineering, construction, mining, construction, glass industry, as well as in many other areas.

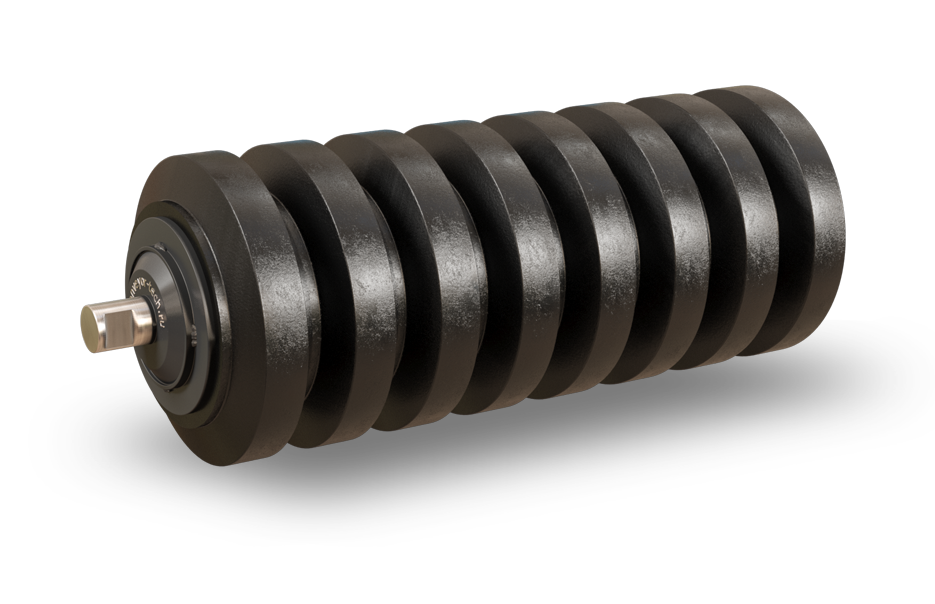

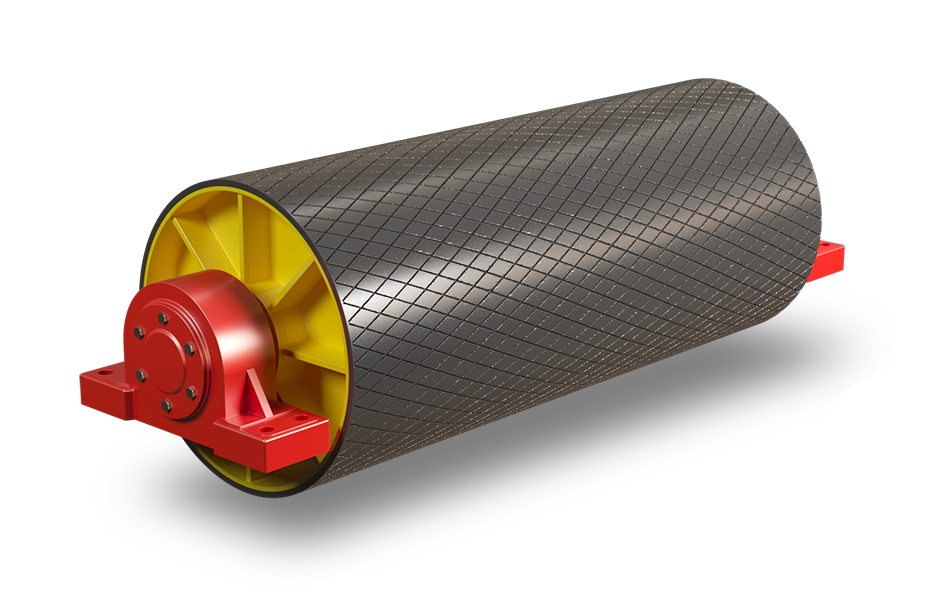

Drive pulley

The drive pulley is the main part of the conveyor belt and is used to move the conveyor belt on the conveyor. To ensure communication with the engine, a transmission mechanism is used and the method of transmission of tractive effort is frictional. We use high quality cast iron or steel for the production of the pulley bearing housings. All conveyor pulleys are designed to provide a long service life. The drive pulley is slightly wider than the conveyor belt itself, which prevents it from sliding off during movement. The pulley is rotated using a reducer driven by an electric motor or a gear motor. The drive pulleys are available in both plain and lined designs. The width and diameter of the pulley is determined by the Customer. Drive pulleys can be manufactured with a double-sided shaft exit for connection with two drive mechanisms located symmetrically about the conveyor axis.

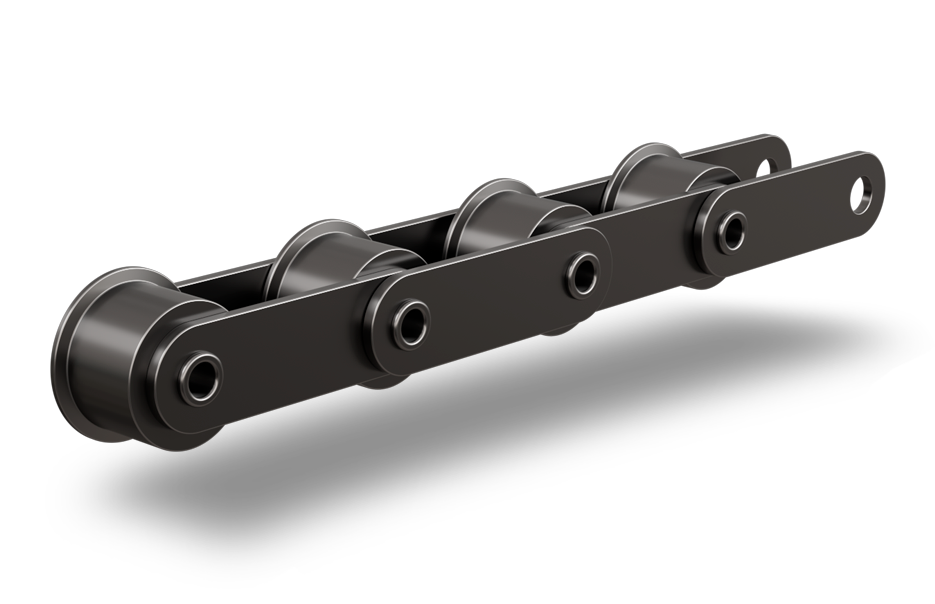

Non-driven conveyor pulleys are an integral part of the belt conveyor. This type of pulleys is designed to tension and increase the adhesion force of the drive pulley with the conveyor belt, the option of slipping the conveyor belt is excluded, and is also used to change the movement of the conveyor belt in horizontally inclined conveyors. Non-driven pulleys are installed in different places of the conveyor line: at the bend, at the points of pulleys are of different types: head, revolving, tension, tail, deviating, pressure and bypass. Our pulleys have an ergonomic body, it is reliably protected from dust and moisture. If necessary, it can be made in a collapsible design, which allows you to quickly carry out preventive work and repair.

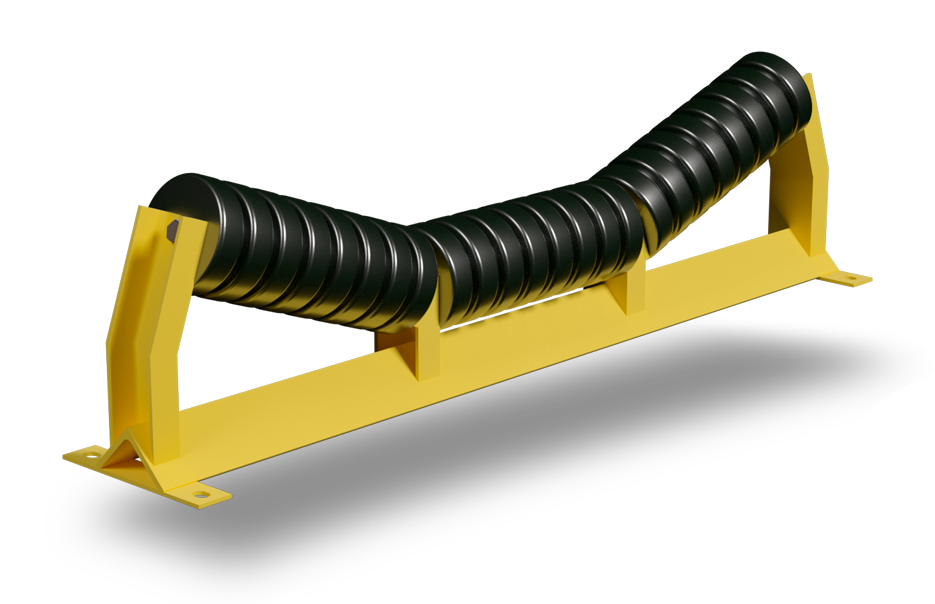

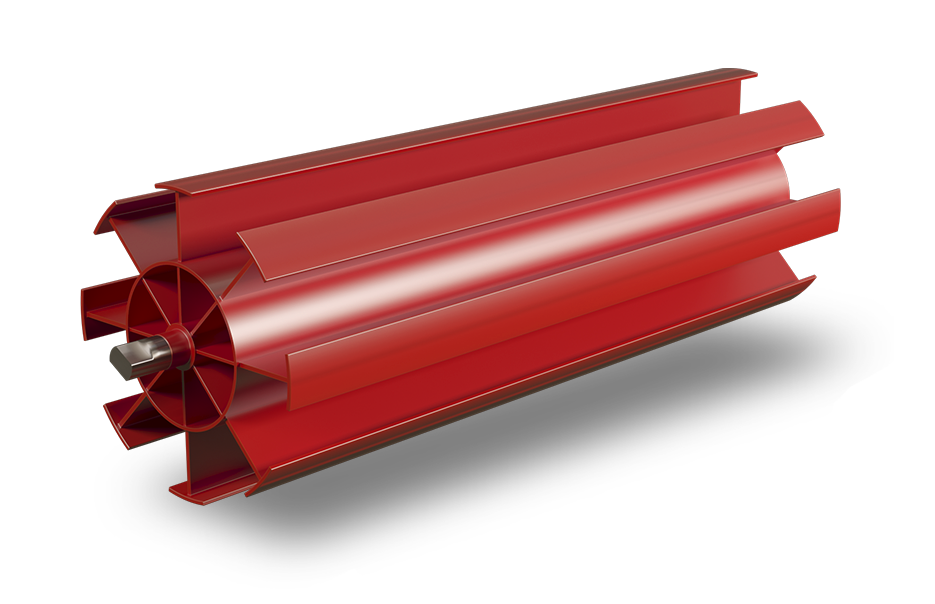

Deflection pulley

The deviating conveyor pulley has great functionality and its main task is to provide a change in the direction of movement of the conveyor belt. The deflection pulley are also used to prevent the conveyor belt from sagging. These pulleys are used on large and long conveyors. They are installed on the conveyor frames, between the tension and drive pulleys. All pulleys that are used in belt conveyors must be durable. Therefore, they are made from general purpose seamless steel pipes. This design is rather simple and does not have any special features; the pulley consists of an outer casing, flanges, a shaft and bearings fixed to it, complete with bearing housings. The number of deflecting pulleys on a conveyor belt depends on the width of the belt itself. For models with a belt width up to 650 mm, one is enough, for larger widths, two are needed.

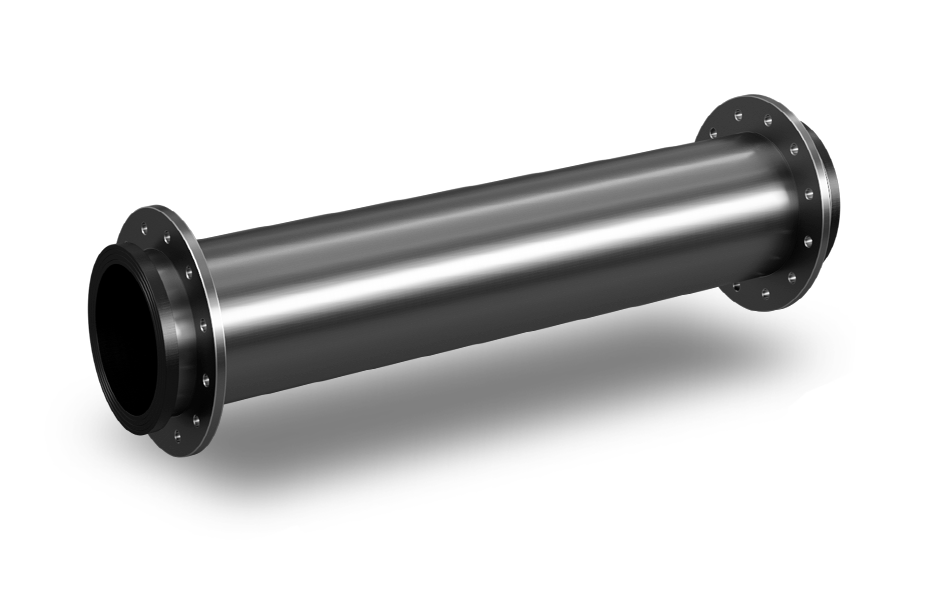

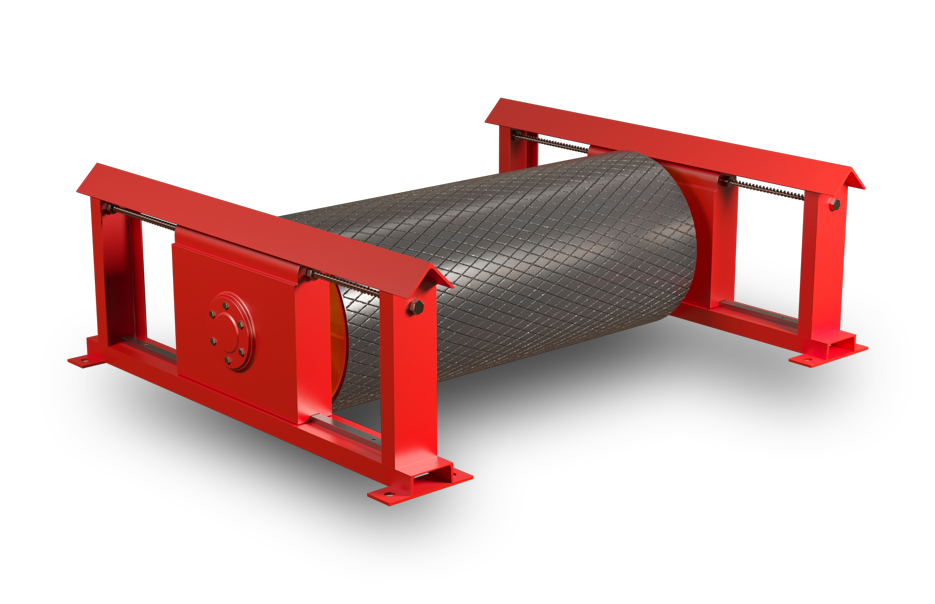

Tension pulley

The tension pulley is located at the tail end of the conveyor and, together with the belt tensioner, constitutes the belt tensioning station. The main structural element of the tension pulley for a conveyor is a shell mounted on support discs that are fixed on the tensioner shaft. The shell has a cylindrical shape. The tension pulley serves to increase the angle of the conveyor belt wrap around the surface of another pulley, to change the position of the conveyor belt and to tension the belt, thereby creating the necessary friction between their surfaces. In addition, the product allows you to prevent slipping of the conveyor belt and its sagging between the rollers.