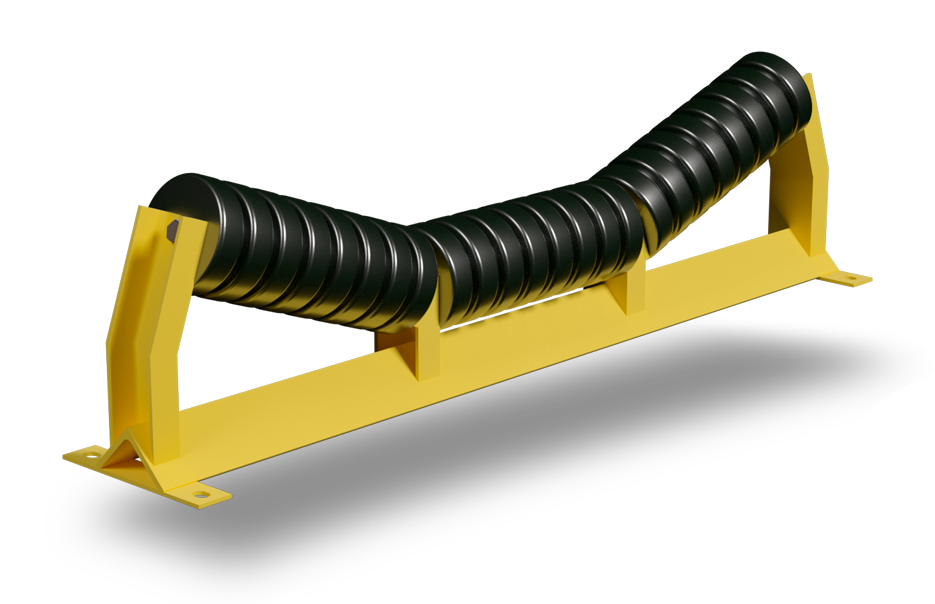

LLC “Conveyor Technologies” is engaged in the development and production of damper stations. A damper station (also referred to as an amortization transfer table) is a system that prevents damage to the conveyor belt and rollers in areas of material transfer. The stations can be used for all types of conveyors, parameters of heights, material size, density and volume of transported material. The damper station is used in coal mines, mines, power plants, etc.

All products of LLC “Conveyer Technologies” are certified and meet high quality and safety requirements.

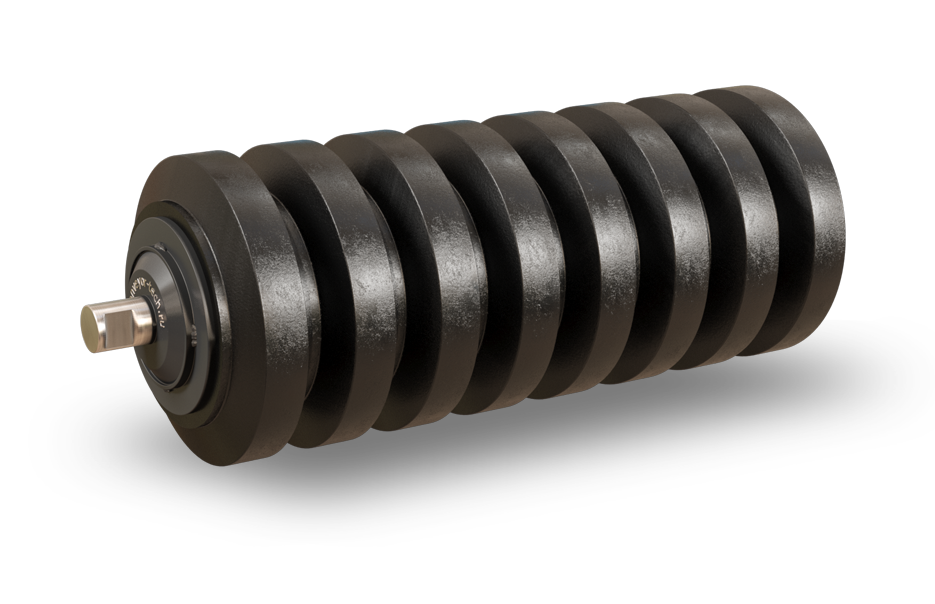

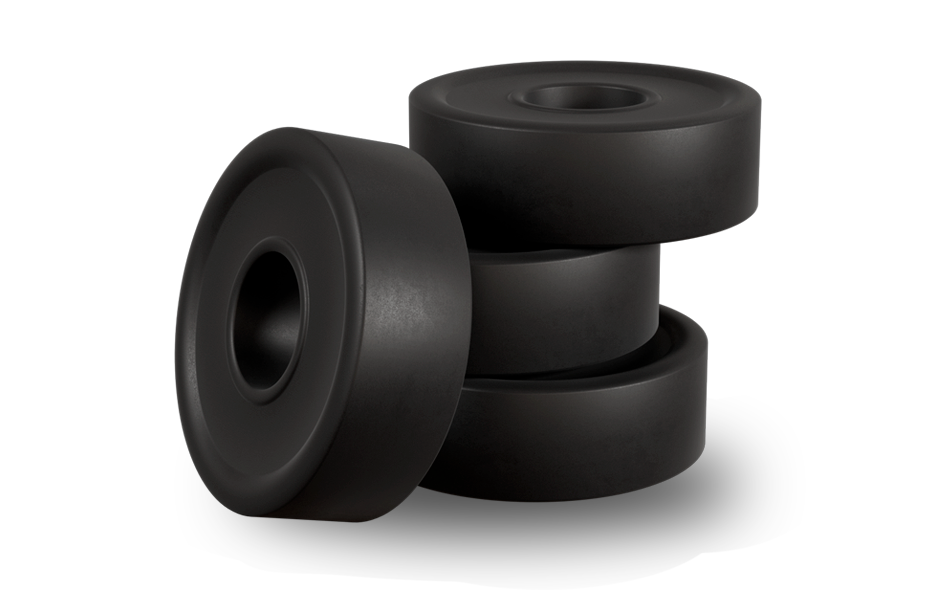

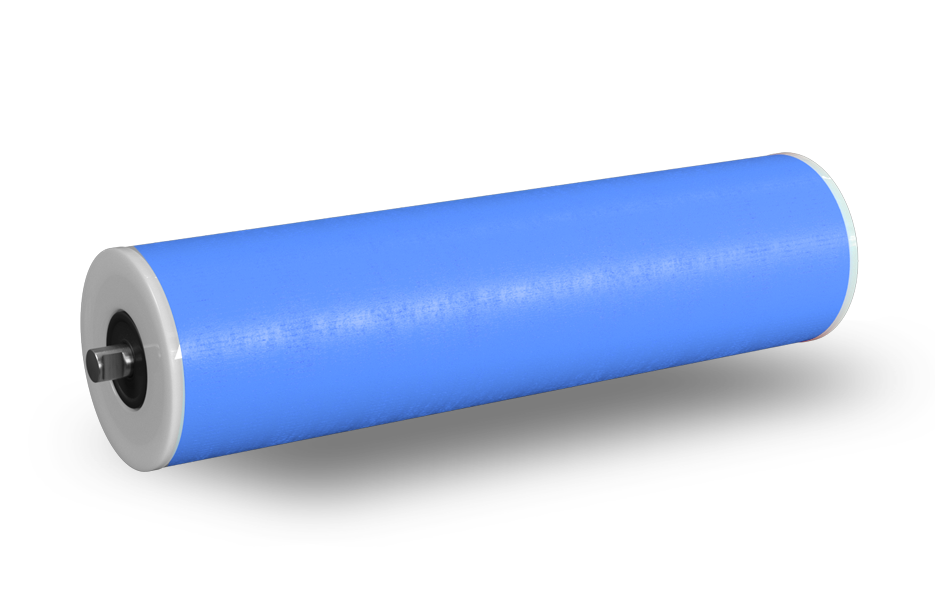

The damper station is used instead of the impact rollers. It consists of shock-absorbing beams that are attached to a metal structure (the so-called bed) by means of T-bolts. The rubber base of the shock-absorbing beam absorbs all the loads of the falling material and “dampens” its kinetic energy. The surface of the shock absorber is covered with high molecular weight polyethylene, which has a low coefficient of friction and high wear resistance.

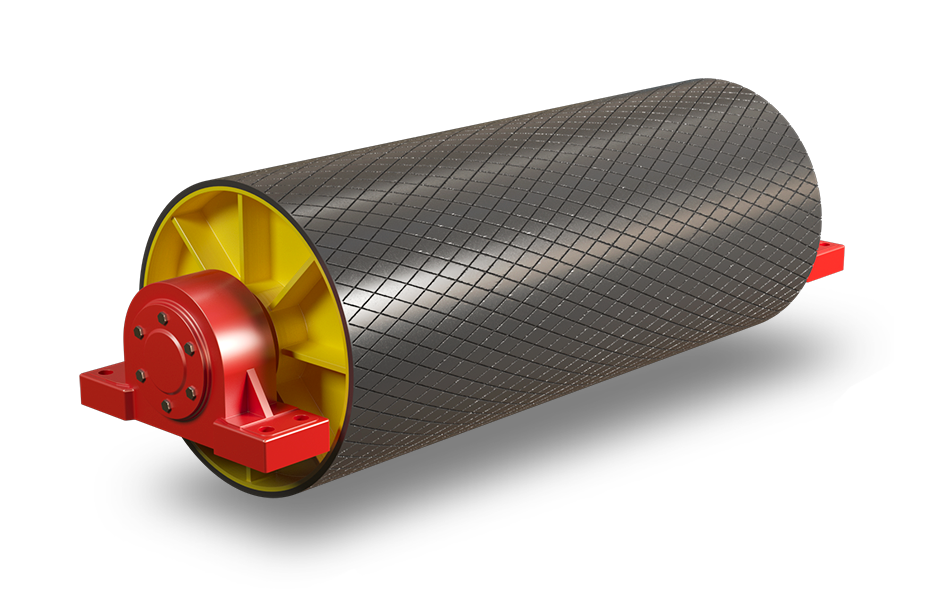

Main features and advantages of the damper station:

– maximum absorption of impact force;

– prevention of damage to the conveyor belt;

– ease of installation and maintenance;

– minimization of the friction force using the surface of high molecular weight polyethylene;

– effective elimination of “splash” of materials due to uneven force on conveyor belts;

– improving the safety of the conveyor.